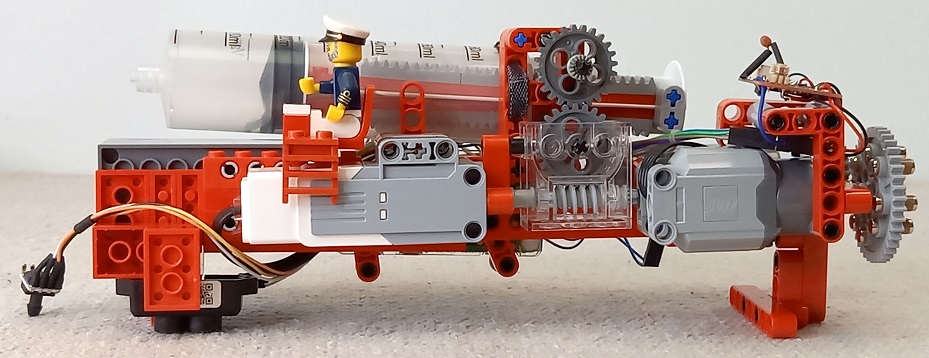

Here is the finished radio-controlled submarine.

Does it work? Yeah, it drives well under water. The automatic depth control really makes controlling it easy, as you can focus on pressing only forward/backward and left/right buttons and forget the dive/surface buttons. I’d say the controls are as good as in Submarine 2.0, which has been the best so far.

Pros? PID control works quite accurately. Seals were always watertight and the hull never leaked. Submarine top speed is the best so far. The main propeller is powerful. Magnetic couplings work more efficiently than before, because of silicone lubricant. More free space inside the hull because of tungsten pellets.

Cons? End caps are time consuming to close, because of the tight seals and the need to equalize internal pressure. Radio control range is short, only 4 meters. Turn propeller is a bit too weak. The submarine won’t drive straight when going top speed, probably because of the flat front. Tungsten pellets are expensive. Laser distance sensor is almost useless, because its range in clear water is only 0.5 meters. Tacho pulses are sometimes lost and you need to fix syringe position parameter. Complex to build.

Do I recommend building this? Not really. It is too complex and time consuming to build. It took me about 300 hours, although a lot was spent in development, mistakes and videography. Unless you want to try PID control specifically, I’d recommend Submarine 2.0 which is simpler and has good controls.

How to improve it? Make the end caps easier to install and add a locking mechanism. Change the radio control board to something more powerful. Remove laser distance sensor. Increase turn propeller size or gear ratio. Make the front more streamlined. Make the syringe position data reliable somehow.

Key features

- Displacement: 2.4 kg

- Test depth: 1.5 m

- Radio control range: 4 m

- Power consumption: 1.4 W idle, 5.6 W max

- Battery runtime: 2 hours

- Top speed: 0.6 knots (0.3 m/s, 1.1 km/h)

Parts

- Hull: acrylic plastic cylinder (250x110x3mm)

- End caps: SAN plastic lid (2mm thick), acrylic plastic cylinder (100x3mm)

- Seal: o-ring 2.5 mm (NBR 70 shore)

- Extra weight: tungsten pellets (2.5 mm diameter, 1.58 kg)

- Ballast tank: 60 ml syringe (Eotia marinade injector)

- Ballast motor: Lego EV3 Medium Servo motor (45503)

- Forward propeller: drone propeller (Diatone Bull Nose 4×4.5)

- Forward motor: Lego PF L-motor (88003)

- Turn propeller: Lego propeller 3 blade (6041)

- Turn motor: Lego PF M-motor (8883)

- Magnets: K&J Magnetics D38-N52 neodymium magnet

- Friction reduction: TapeCase 423-5 UHMW Tape, silicon spray

- Motor driver: Pololu 2130 DRV8833 Dual H-bridge

- Radio control: 27 MHz controller dissembled from a toy submarine (no-name chinese Mini U Boat)

- Pressure sensor: Honeywell SSCMANV030PA2A3 2 bar

- Laser distance sensor: SparkFun TFMini-S Micro

- Computer: Raspberry Pi Zero 2 W

- Power supply: Lego Rechargeable Battery Box 9V (8878)

- Voltage regulator: Pololu 2123 S7V8F5 5V

Lego parts

1x 8878 Power Functions Rechargeable Battery Box 1x 99455 Electric, Motor EV3, Medium 1x 45514 Cable Pack EV3 1x 88003 Power Functions L-Motor 1x 8883 Power Functions M-Motor 2x 8886 Power Functions Extension Wire (20cm) 1x 6041 Propeller 3 Blade 3 Diameter with Axle Hole 1x col154 Sea Captain, Series 10 (Minifigure Only without Stand and Accessories) 1x 4079b Minifigure, Utensil Seat / Chair 2 x 2 with Center Sprue Mark 1x 3069bp68 Tile 1 x 2 with Groove with Red and Yellow Controls and Two White Stripes on Left Pattern 1x 4175 Ladder 1 1/2 x 2 x 2 2x 3649 Technic, Gear 40 Tooth 4x 3648 Technic, Gear 24 Tooth (2nd Version - 1 Axle Hole) 2x 6589 Technic, Gear 12 Tooth Bevel 4x 10928 Technic, Gear 8 Tooth with Dual Face 1x 4716 Technic, Gear Worm Screw, Long 6x 3743 Technic, Gear Rack 1 x 4 1x 6588 Technic, Gearbox 2 x 4 x 3 1/3 1x 48496 Technic, Pin Connector Toggle Joint Smooth Double with 2 Pins 2x 32530 Technic, Pin Connector Plate 1 x 2 x 1 2/3 with 2 Holes (Double on Top) 2x 62462 Technic, Pin Connector Round 2L with Slot (Pin Joiner Round) 2x 6558 Technic, Pin 3L with Friction Ridges 28x 4459 Technic, Pin with Friction Ridges without Center Slots 1x 32002 Technic, Pin 3/4 6x 4274 Technic, Pin 1/2 without Friction Ridges 6x 3713 Technic Bush 3x 4265c Technic Bush 1/2 Smooth 22x 4265a Technic Bush 1/2 Toothed, Four Interior Ridges 1x 3737 Technic, Axle 10L 2x 44294 Technic, Axle 7L 2x 3706 Technic, Axle 6L 5x 3705 Technic, Axle 4L 2x 18651 Technic, Axle 2L with Pin with Friction Ridges 4x 43093 Technic, Axle 1L with Pin with Friction Ridges 1x 3703 Technic, Brick 1 x 16 with Holes 1x 2730 Technic, Brick 1 x 10 with Holes 1x 3894 Technic, Brick 1 x 6 with Holes 1x 3701 Technic, Brick 1 x 4 with Holes 1x 32525 Technic, Liftarm Thick 1 x 11 1x 32524 Technic, Liftarm Thick 1 x 7 1x 32316 Technic, Liftarm Thick 1 x 5 4x 32523 Technic, Liftarm Thick 1 x 3 1x 43857 Technic, Liftarm Thick 1 x 2 2x 18654 Technic, Liftarm Thick 1 x 1 (Spacer) 4x 32526 Technic, Liftarm, Modified Bent Thick L-Shape 3 x 5 1x 32140 Technic, Liftarm, Modified Bent Thick L-Shape 2 x 4 4x 60484 Technic, Liftarm, Modified T-Shape Thick 3 x 3 3x 32056 Technic, Liftarm, Modified Bent Thin L-Shape 3 x 3 2x 41677 Technic, Liftarm Thin 1 x 2 - Axle Holes 2x 4032 Plate, Round 2 x 2 with Axle Hole 3x 3020 Plate 2 x 4 1x 3021 Plate 2 x 3 2x 60479 Plate 1 x 12 1x 4477 Plate 1 x 10 3x 3666 Plate 1 x 6 1x 3710 Plate 1 x 4 2x 3023 Plate 1 x 2 1x 3069 Tile 1 x 2 1x 3003 Brick 2 x 2 1x 3001 Brick 2 x 4 1x 3004 Brick 1 x 2

Cost

- 236 EUR tungsten pellets

- 100 EUR Lego rechargeable battery box

- 55 EUR laser distance sensor TFMini-S Micro

- 36 EUR acrylic plastic hull

- 35 EUR pressure sensor SSCMANV030PA2A3

- 33 EUR radio control (mini u-boat)

- 28 EUR Raspberry Pi Zero 2 W

- 25 EUR Lego Medium motor EV3

- 24 EUR magnets

- 22 EUR crimp tool

- 21 EUR Lego M-Motor

- 20 EUR pin header connector kit

- 20 EUR voltage regulator

- 18 EUR o-ring cord

- 18 EUR Lego L-Motor

- 10 EUR motor drivers

- 6 EUR Lego captain

- 5 EUR clear case for Raspberry Pi Zero

- 5 EUR SAN plastic lid

- 4 EUR syringe

- 3 EUR wire

- 1 EUR main propeller

- 50 EUR other Lego parts

- TOTAL COST: 800 EUR

Interior images

Testing images

Video

Here is a YouTube video of this project. From 2:30 onward you find test footage from the water container, swimming pool, and river.

And here is the entire 20 minute dive in the river.

Code

Python implementation and logs for download:

https://mega.nz/folder/wqhhxJoI#cHnVI6NjaPkfZcdZvFZZ0Q

or

https://www.dropbox.com/sh/u8a45maz3brrwrw/AADbUx9VZEw5UJPny1bJI-Lwa

Python implementation for the submarine:

#################################################

# Submarine 4.0

# Created by: Brick Experiment Channel

# Hardware:

# Raspberry Pi Zero 2 W

# Honeywell SSCMANV030PA2A3 pressure sensor

# SparkFun TFMini-S Micro laser distance sensor

# Pololu 2130 DRV8833 motor drivers

# Pololu 2123 S7V8F5 5V Voltage regulator

# 27MHz radio controller from a toy submarine

# Lego EV3 Medium motor for syringe ballast tank

# Lego PF Large motor for forward propeller

# Lego PF Medium motor for turn propeller

#

#################################################

#settings

SYRINGE_POS_MIN = 3 #syringe ballast min pos [ml]

SYRINGE_POS_MAX = 45 #syringe ballast max pos [ml]

SYRINGE_TACHO_COUNT = 19000 #tacho count from syringe min to max pos

SYRINGE_HYSTERESIS = 360 #syringe+gearbox backlash/hysteresis [tacho counts]

SYRINGE_DEADBAND = 0.5 #deadband to reduce motor wear [ml]

SYRINGE_NEUTRAL_POS = 30 #neutral buoyancy position [ml]

DEPTH_FILTER = 0.90 #pressure sensor depth EMA filter ratio [0...1]

DISTANCE_FILTER = 0.95 #laser distance EMA filter ratio [0...1]

KD_FILTER = 0.95 #derivative EMA filter ratio [0...1]

MAX_DEPTH = 4 #maximum limit for depth control [m]

MAX_DISTANCE = 1 #maximum limit for laser distance [m]

KP = 30 #PID proportional factor

KI = 1 #PID integral factor

KD = 200 #PID derivative factor

SLEEP_TIME = 20 #main loop sleep [ms]

#################################################

from time import sleep, perf_counter_ns

from datetime import datetime

import math

import signal

import smbus

import configparser

from serial import Serial

from gpiozero import DigitalInputDevice, DigitalOutputDevice, PWMOutputDevice, Button

from gpiozero import LoadAverage, CPUTemperature

#syringe control mode

MODE_DIRECT = 0 #no PID (radio buttons control syringe directly)

MODE_PID = 1 #PID over pressure sensor (buttons change target depth)

MODE_PID_LASER = 2 #PID over laser sensor (buttons change target distance to sea floor)

controlMode = MODE_DIRECT

targetDepth = 0.10 #[m]

targetDistance = 0.10 #[m]

#read config file

configFile = open("submarine_4.ini", "r+")

config = configparser.ConfigParser()

config.read_file(configFile)

tachoCount = int(config['default']['tachoCount'])

storedTachoCount = tachoCount

def writeConfigFile():

global configFile

global config

global tachoCount

global storedTachoCount

if tachoCount != storedTachoCount:

storedTachoCount = tachoCount

config['default'] = {}

config['default']['tachoCount'] = str(tachoCount)

configFile.seek(0)

config.write(configFile)

configFile.truncate()

#prepare pressure sensor

bus = smbus.SMBus(1)

def readPressureSensor():

#read data

PRESSURE_SENSOR_ADDR = 0x28

data = bus.read_i2c_block_data(PRESSURE_SENSOR_ADDR, 0x00, 4)

status = (data[0] & 0xC0) >> 6

pressCounts = data[1] | ((data[0] & 0x3F) << 8)

tempCounts = ((data[3] & 0xE0) >> 5) | (data[2] << 3)

#pressure conversion

P_MAX = 2 #[bar]

P_MIN = 0 #[bar]

O_MAX = 0.9 * pow(2,14)

O_MIN = 0.1 * pow(2,14)

pressure = (pressCounts - O_MIN) * (P_MAX - P_MIN) / (O_MAX - O_MIN) + P_MIN #[bar]

#temperature conversion

T_MAX = 150 #[Celsius]

T_MIN = -50 #[Celsius]

T_COUNTS = pow(2,11) - 1

temperature = tempCounts * (T_MAX - T_MIN) / T_COUNTS + T_MIN #[Celsius]

return pressure, temperature

#prepare laser distance sensor

serial = Serial("/dev/serial0", 115200, timeout=0.01)

serial.write([0x5A,0x05,0x05,0x06,0x6A]) #set unit to mm

serial.write([0x5A,0x06,0x03,0x64,0x00,0x39]) #set frame rate to 100 Hz

serial.write([0x5A,0x09,0x3B,0x00,0x00,0x00,0x00,0x00,0x62]) #set I/O mode to standard

sleep(0.1)

serial.reset_input_buffer()

def readLaserSensor():

#skip old serial data

FRAME_SIZE = 9

while (serial.inWaiting() > FRAME_SIZE):

serial.read()

#read data

data = serial.read(FRAME_SIZE)

#parse data

distance = float('nan')

strength = float('nan')

temperature = float('nan')

if len(data) == FRAME_SIZE and data[0] == 0x59 and data[1] == 0x59:

checksum = 0

for i in range(0, FRAME_SIZE - 1):

checksum = checksum + data[i]

checksum = checksum & 0xFF

if checksum == data[FRAME_SIZE - 1]:

distance = data[2] | data[3] << 8 #[mm]

strength = data[4] | data[5] << 8 #[0-65536]

temperature = data[6] | data[7] << 8

distance = distance / 1000 #[m]

temperature = temperature / 8 - 256 #[C]

#scale for water

SPEED_IN_AIR = 299000 #[km/s]

SPEED_IN_WATER = 225000 #[km/s]

distance *= SPEED_IN_WATER / SPEED_IN_AIR

return distance, strength, temperature

#prepare motor drivers

motorForward = PWMOutputDevice(22)

motorForward.frequency = 1000

motorBackward = PWMOutputDevice(27)

motorBackward.frequency = 1000

motorLeft = DigitalOutputDevice(17)

motorRight = DigitalOutputDevice(18)

motorDive = DigitalOutputDevice(13)

motorSurface = DigitalOutputDevice(12)

#prepare radio control

radioPower = DigitalOutputDevice(25)

buttonForward = Button(24, hold_time=1.0)

buttonBackward = Button(23, hold_time=1.0)

buttonLeft = Button(9)

buttonRight = Button(10)

buttonDive = Button(11, bounce_time=None, hold_time=1.0, hold_repeat=True)

buttonSurface = Button(8, bounce_time=None, hold_time=1.0, hold_repeat=True)

def changeTargetDepth(value):

global controlMode

global targetDepth

global targetDistance

if controlMode == MODE_PID:

targetDepth += value

if targetDepth < 0:

targetDepth = 0

if targetDepth > MAX_DEPTH:

targetDepth = MAX_DEPTH

print("targetDepth=%.0f cm" % (targetDepth*100))

elif controlMode == MODE_PID_LASER:

targetDistance -= value

if targetDistance < 0.1:

targetDistance = 0.1

if targetDistance > MAX_DISTANCE:

targetDistance = MAX_DISTANCE

print("targetDistance=%.0f cm" % (targetDistance*100))

def buttonDive_pressed():

changeTargetDepth(0.1)

def buttonDive_held():

changeTargetDepth(0.5)

def buttonSurface_pressed():

changeTargetDepth(-0.1)

def buttonSurface_held():

changeTargetDepth(-0.5)

def buttonForward_pressed():

motorForward.value = 0.6

def buttonForward_held():

motorForward.value = 1

def buttonForward_released():

motorForward.value = 0

def buttonBackward_pressed():

motorBackward.value = 0.6

def buttonBackward_held():

motorBackward.value = 1

def buttonBackward_released():

motorBackward.value = 0

def buttonLeft_pressed():

motorLeft.value = 1

def buttonLeft_released():

motorLeft.value = 0

def buttonRight_pressed():

motorRight.value = 1

def buttonRight_released():

motorRight.value = 0

buttonForward.when_pressed = buttonForward_pressed

buttonForward.when_held = buttonForward_held

buttonForward.when_released = buttonForward_released

buttonBackward.when_pressed = buttonBackward_pressed

buttonBackward.when_held = buttonBackward_held

buttonBackward.when_released = buttonBackward_released

buttonLeft.when_pressed = buttonLeft_pressed

buttonLeft.when_released = buttonLeft_released

buttonRight.when_pressed = buttonRight_pressed

buttonRight.when_released = buttonRight_released

buttonDive.when_pressed = buttonDive_pressed

buttonDive.when_held = buttonDive_held

buttonSurface.when_pressed = buttonSurface_pressed

buttonSurface.when_held = buttonSurface_held

#prepare tachometers

tachoPower = DigitalOutputDevice(20)

tachoA = DigitalInputDevice(16)

tachoB = DigitalInputDevice(19)

tachoAValue = tachoA.value

tachoBValue = tachoB.value

def tachoA_rising():

global tachoCount

global tachoAValue

global tachoBValue

tachoAValue = 1

if tachoBValue == 0:

#A in rising edge and B in low value

# => direction is clockwise (shaft end perspective)

tachoCount += 1

else:

tachoCount -= 1

def tachoA_falling():

global tachoAValue

tachoAValue = 0

def tachoB_rising():

global tachoCount

global tachoAValue

global tachoBValue

tachoBValue = 1

if tachoAValue == 0:

tachoCount -= 1

else:

tachoCount += 1

def tachoB_falling():

global tachoBValue

tachoBValue = 0

tachoA.when_activated = tachoA_rising

tachoA.when_deactivated = tachoA_falling

tachoB.when_activated = tachoB_rising

tachoB.when_deactivated = tachoB_falling

tachoPower.value = 1

#exit program when Ctrl-C is pressed

exitRequested = False

def sigintHandler(sig, frame):

print("Ctrl-C pressed, exit program")

global exitRequested

exitRequested = True

signal.signal(signal.SIGINT, sigintHandler)

signal.signal(signal.SIGTERM, sigintHandler)

def sign(x):

if x > 0: return 1

elif x < 0: return -1

else: return 0

print("program started")

sleep(0.1)

startTime = perf_counter_ns()

prevLoopTime = perf_counter_ns()

prevModeButtonTime = perf_counter_ns()

prevRadioResetTime = perf_counter_ns()

prevTaskTime = perf_counter_ns()

prevLogTime = perf_counter_ns()

prevPrintTime = perf_counter_ns()

trueTachoCount = 0

depthZeroPoint = float('nan')

depthFiltered = 0

laserDistanceValidTime = 0

laserDistanceFiltered = 0

modeButtonStep = 0

error = 0

integral = 0

derivative = 0

PIDoutput = 0

prevError = float('nan')

prevDerivative = 0

syringeTargetPos = 0

deadbandDir = 0

cpuTemp = float('nan')

logFile = None

logData = []

loopCount = 0

while not exitRequested:

timeDelta = (perf_counter_ns() - prevLoopTime) / 1e9 #[sec]

prevLoopTime = perf_counter_ns()

secondsSinceStart = (perf_counter_ns() - startTime) / 1e9

#calculate syringe position

if tachoCount > trueTachoCount:

trueTachoCount = tachoCount

elif tachoCount < trueTachoCount - SYRINGE_HYSTERESIS:

trueTachoCount = tachoCount + SYRINGE_HYSTERESIS

syringePos = SYRINGE_POS_MIN + SYRINGE_POS_MAX * \

trueTachoCount / SYRINGE_TACHO_COUNT #[ml]

#read pressure sensor

pressure, pressureSensorTemp = readPressureSensor()

#calculate depth

GRAVITY = 9.80665 #[m/s2]

WATER_DENSITY = 998 #fresh water at 20 Celsius [kg/m3]

pressurePa = pressure * 100000 #[Pa]

depth = pressurePa / (GRAVITY * WATER_DENSITY) #[m]

#adjust for depth zero point

if math.isnan(depthZeroPoint): depthZeroPoint = depth

if syringePos <= 0:

#when syringe is empty, assume we are in surface and start adjusting

depthZeroPoint = 0.01 * depth + 0.99 * depthZeroPoint

depth -= depthZeroPoint

#filter depth (exponential moving average)

depthFiltered = (1 - DEPTH_FILTER) * depth + DEPTH_FILTER * depthFiltered

#read laser sensor

laserDistance, laserStrength, laserTemp = readLaserSensor()

#fix laser data for close distance (when sensor says 0.05m it is actually 0.10m)

laserDistanceFixed = laserDistance

if laserDistanceFixed < 0.25:

laserDistanceFixed += 0.5 * (0.25 - laserDistanceFixed) * \

math.sqrt(laserDistanceFixed / 0.25)

#omit unreliable laser data

if laserStrength < 300 or laserDistance > 10:

laserDistanceFixed = float('nan')

if (perf_counter_ns() - laserDistanceValidTime) / 1e9 >= 1.0:

laserDistanceFiltered = float('nan')

else:

if math.isnan(laserDistanceFiltered):

laserDistanceFiltered = laserDistanceFixed

laserDistanceValidTime = perf_counter_ns()

#filter laser distance (exponential moving average)

if not math.isnan(laserDistanceFixed):

laserDistanceFiltered = (1 - DISTANCE_FILTER) * laserDistanceFixed + \

DISTANCE_FILTER * laserDistanceFiltered

#calculate syringe neutral position

# hull compression compensation (15 ml at 100 cm depth)

syringeNeutralPos = SYRINGE_NEUTRAL_POS

if depthFiltered > 1:

syringeNeutralPos -= 15

elif depthFiltered > 0:

syringeNeutralPos -= math.sqrt(depthFiltered) * 15 / 1

#change depth control mode

# triggered by button sequences

# MODE_DIRECT = Surface-Dive-Surface

# MODE_PID = Surface-Dive-Right

# MODE_PID_LASER = Surface-Dive-Left

changeMode = False

if buttonSurface.value == 1:

if modeButtonStep == 0:

prevModeButtonTime = perf_counter_ns()

modeButtonStep = 1

if modeButtonStep == 2:

modeButtonStep = 3

controlMode = MODE_DIRECT

print("MODE_DIRECT")

if buttonDive.value == 1:

if modeButtonStep == 1:

modeButtonStep = 2

if buttonRight.value == 1:

if modeButtonStep == 2:

modeButtonStep = 3

controlMode = MODE_PID

print("MODE_PID")

if buttonLeft.value == 1:

if modeButtonStep == 2:

modeButtonStep = 3

controlMode = MODE_PID_LASER

print("MODE_PID_LASER")

if modeButtonStep != 0 and (perf_counter_ns() - prevModeButtonTime) / 1e9 >= 1.5:

modeButtonStep = 0

#control syringe motor

syringeMotorCtrl = 0

if controlMode == MODE_DIRECT:

if buttonDive.value == 1: syringeMotorCtrl = 100

elif buttonSurface.value == 1: syringeMotorCtrl = -100

elif controlMode == MODE_PID:

if targetDepth <= 0:

#go to surface

if syringePos > 0:

syringeMotorCtrl = -100

else:

syringeMotorCtrl = 0

else:

#PID controller

error = targetDepth - depthFiltered

integral += error * timeDelta

if math.isnan(prevError) or buttonDive.value == 1 or buttonSurface.value == 1:

prevError = error

derivative = (error - prevError) / timeDelta

derivative = (1 - KD_FILTER) * derivative + KD_FILTER * prevDerivative

PIDoutput = KP * error + KI * integral + KD * derivative

prevError = error

prevDerivative = derivative

#move syringe to the target position

syringeTargetPos = syringeNeutralPos + PIDoutput #[ml]

syringeMotorCtrl = syringeTargetPos - syringePos

elif controlMode == MODE_PID_LASER:

if depthFiltered >= MAX_DEPTH:

#limit to max depth

syringeMotorCtrl = -100

elif math.isnan(laserDistanceFixed):

#bottom too far for laser -> increase depth

syringeMotorCtrl = 100

else:

#PID controller

error = laserDistanceFiltered - targetDistance

integral += error * timeDelta

if math.isnan(prevError) or buttonDive.value == 1 or buttonSurface.value == 1:

prevError = error

derivative = (error - prevError) / timeDelta

derivative = (1 - KD_FILTER) * derivative + KD_FILTER * prevDerivative

PIDoutput = KP * error + KI * integral + KD * derivative

prevError = error

prevDerivative = derivative

#move syringe to the target position

syringeTargetPos = syringeNeutralPos + PIDoutput #[ml]

syringeMotorCtrl = syringeTargetPos - syringePos

#syringe deadband limitation

if abs(syringeMotorCtrl) > SYRINGE_DEADBAND:

deadbandDir = sign(syringeMotorCtrl)

if sign(syringeMotorCtrl) != sign(deadbandDir):

deadbandDir = 0

if deadbandDir == 0:

syringeMotorCtrl = 0

#syringe range limitation

if syringePos <= SYRINGE_POS_MIN and syringeMotorCtrl < 0:

syringeMotorCtrl = 0

if syringePos >= SYRINGE_POS_MAX and syringeMotorCtrl > 0:

syringeMotorCtrl = 0

#drive syringe motor

motorDive.value = (syringeMotorCtrl > 0)

motorSurface.value = (syringeMotorCtrl < 0)

#radio controller fix

# the radio board has an auto-surface safety feature

# after 10 secs of silence it will force the surface button on

# to fix it, we will quickly power off and on the radio every 9 secs

if (buttonDive.value == 1 or buttonForward.value == 1 or

buttonBackward.value == 1 or buttonLeft.value == 1 or buttonRight.value == 1):

prevRadioResetTime = perf_counter_ns()

secsSinceRadioReset = (perf_counter_ns() - prevRadioResetTime) / 1e9

if secsSinceRadioReset > 9:

radioPower.value = 0

prevRadioResetTime = perf_counter_ns()

else:

radioPower.value = 1

#low frequency tasks

if (perf_counter_ns() - prevTaskTime) / 1e9 >= 1.0:

prevTaskTime = perf_counter_ns()

#get info from raspberry

cpuTemp = CPUTemperature().temperature

#write config file

writeConfigFile()

#debug data

motorsState = (motorForward.value > 0) | (motorBackward.value > 0) << 1 | \

motorLeft.value << 2 | motorRight.value << 3 | \

motorDive.value << 4 | motorSurface.value << 5

buttonsState = buttonForward.value | buttonBackward.value << 1 | \

buttonLeft.value << 2 | buttonRight.value << 3 | \

buttonDive.value << 4 | buttonSurface.value << 5

#log data for post analysis

logLine = [secondsSinceStart, pressure, depth, depthZeroPoint,

depthFiltered, targetDepth, laserDistance,

laserStrength, laserDistanceFiltered, targetDistance,

tachoCount, trueTachoCount,

syringePos, syringeTargetPos, syringeNeutralPos,

error, integral, derivative, PIDoutput, syringeMotorCtrl,

controlMode, motorsState, buttonsState, radioPower.value,

pressureSensorTemp, laserTemp, cpuTemp]

logData.append([])

for value in logLine:

strValue = None

if type(value) == float: strValue = str('%.5g' % value)

else: strValue = str(value)

logData[-1].append(strValue)

#write log data to file

if (perf_counter_ns() - prevLogTime) / 1e9 >= 1.0:

prevLogTime = perf_counter_ns()

if logFile == None:

filename = "datalog_" + datetime.now().strftime("%Y%m%d_%H%M%S") + ".dat"

logFile = open(filename, "w")

logHeader = [["# Submarine 4.0 log"]]

logHeader += [["# SETTINGS:","SYRINGE_POS_MIN",SYRINGE_POS_MIN,

"SYRINGE_POS_MAX",SYRINGE_POS_MAX,

"SYRINGE_TACHO_COUNT",SYRINGE_TACHO_COUNT,

"SYRINGE_HYSTERESIS",SYRINGE_HYSTERESIS,

"SYRINGE_DEADBAND",SYRINGE_DEADBAND,

"SYRINGE_NEUTRAL_POS",SYRINGE_NEUTRAL_POS,

"DEPTH_FILTER",DEPTH_FILTER,

"DISTANCE_FILTER",DISTANCE_FILTER,

"KD_FILTER",KD_FILTER,

"MAX_DEPTH",MAX_DEPTH,

"MAX_DISTANCE",MAX_DISTANCE,

"KP",KP,"KI",KI,"KD",KD,

"SLEEP_TIME",SLEEP_TIME]]

logHeader += [["#"]]

logHeader += [["secondsSinceStart","pressure","depth","depthZeroPoint",

"depthFiltered","targetDepth","laserDistance",

"laserStrength","laserDistanceFiltered","targetDistance",

"tachoCount","trueTachoCount",

"syringePos","syringeTargetPos","syringeNeutralPos",

"error","integral","derivative","PIDoutput","syringeMotorCtrl",

"controlMode","motorsState","buttonsState","radioPower",

"pressureSensorTemp","laserTemp","cpuTemp"]]

logData = logHeader + logData

for logLine in logData:

for value in logLine:

logFile.write(str(value) + ' ')

logFile.write('\n')

logFile.flush()

logData.clear()

#debug print

if (perf_counter_ns() - prevPrintTime) / 1e9 >= 1.0:

secondsSinceLastPrint = (perf_counter_ns() - prevPrintTime) / 1e9

prevPrintTime = perf_counter_ns()

loopInterval = secondsSinceLastPrint / loopCount * 1000

loopCount = 0

print("mode %.0f, depth %.1f, laser %.1f, tacho %.0f, syPos %.1f, loop %.1f"

% (controlMode, depthFiltered*100, laserDistanceFiltered*100,

tachoCount, syringePos, loopInterval))

sleep(SLEEP_TIME / 1000)

loopCount += 1

#stop motors and power down components

motorForward.value = 0

motorBackward.value = 0

motorLeft.value = 0

motorRight.value = 0

motorDive.value = 0

motorSurface.value = 0

radioPower.value = 0

tachoPower.value = 0

writeConfigFile()

print("storedTachoCount=%i, syringePos=%.1f" % (storedTachoCount, syringePos))

print("program ended")

Read through the whole thing. This is so interesting! Your channel is well underrated and this is going to help a ton of people including me 🙂

LikeLiked by 1 person

btw, if you can please upload the full 20 minute run through the river (unlisted, linked in the video desc). It could be very relaxing for some people 🙂

LikeLiked by 1 person

Good idea. The 20 min footage is now linked in the video desc and also embedded in this blog post.

LikeLiked by 1 person

Thanks for providing instructions for building Submarine 4.0,

Do you have a guide for building Submarine 2.0? Because I am looking for a parts list and step by step instructions. I am very interested in building that model since it isn’t as expensive as the current 4.0 model and it still turns out amazing.

Thanks, Josh.

LikeLike

Are you going to bulid 5.0 version or 4.1? That will be easy and recommended to build?

LikeLike

5.0. It should have a major new idea I haven’t explored yet. To make it interesting and entertaining for Youtube. I haven’t thought about it yet.

LikeLiked by 2 people

Nice work ! don´t give up. I made some comments on the FB post in our robotics and RPI PICO group. Now I see the bad hydrodynamics is mentioned in your nice blog as an issue, yes a big one ! You need to improve this for the next project, but not only the nose, also the back should be round because of drag, then you will steer it much better. you are correct you can not steer it with a flat nose, you have built a brake. I loved the PID and the TOF sensors. using RPI for this is overkill, you should probably go for a smaller MPU, either the PICO or an ESP32. Well done ! and congrats again.

LikeLike

Thanks for the shoutouts. Good point about the flat back. The reason why I only mentioned making the front streamlined, is because that should be an easy improvement. The back has magnetic couplings that require a flat area to work. Making the back round would be more difficult.

LikeLiked by 1 person

Hey!

Really, very interesting and intelligent. Thanks for the content! Your integration of scientific theory, investigation/brain storming, problem solving, practicality, computer science, hardware/electronic work, and everything else involved is impressive beyond words.

Something that seems so silly, yet involves such high level/culminated human areas of thought on many fronts. And then the communication and data/progress organization for presentation.

SUPER high level.

May I ask what kind of education/work/personal experiences led you to be able to do something like this, in this way?

LikeLiked by 1 person

Thanks Ryan. Very kind words.

Well, I have the most work experience in coding. That obviously helped a lot here. Also, I’ve done 3 submarines previously and an Inverted Pendulum project where I used PID control.

Basically, you learn by doing, one step at a time. It’s not rocket science (yet :)). Complex things are just a collection of simple things anyone could learn if you spend enough time with it. I think most of you readers could finish a similar submarine project successfully if you spent like 500 hours on it. I had to spend only 300 hours since I had experience.

LikeLiked by 1 person

Maybe try ISM spectrum (sub 1GHz) transceivers , eg. from https://www.hoperf.com/ There are three identically priced models available: RFM96 (433MHz), RFM95 (868MHz), RFM95 (915MHz) and a slightly cheaper RFM98 (433MHz). Works with Arduino library https://github.com/jgromes/RadioLib

Love the captain although at a certain point using Lego is cute but really impractical.

Software wise the next version could try using one of the existing open source drone OS projects instead of a custom system. This will likely be more maintainable and get you free features.

Optional design challenge: survive the dangerous waters of a Finnish spa.

LikeLike

What camera are you using for the project?

LikeLike

Main camera for video: Sony AX43

Underwater shots: GoPro HERO8

Onboard camera in the river: RunCam 5

Most images in this blog: Samsung A41 phone

LikeLike

thank you, can you also tell me how you get the status information about time, temperature, depth, in the video?

I assume the video is not controlled by the raspberry pi ……

LikeLike

Sure. Raspberry Pi writes the status information into a log file. I take the log file and run it through a script that creates a video file with changing labels. Then in Premiere I just layer the info video on top of the onboard video footage.

I can put the script somewhere for download if you want to take a closer look.

LikeLike

Thank you….Yes please upload the script I would be very interested to have a look on how you did that.

/michael

LikeLike

https://www.dropbox.com/sh/u8a45maz3brrwrw/AADbUx9VZEw5UJPny1bJI-Lwa?preview=log_to_label_video.py

It uses matplotlib TextBox as labels and ffmpeg to create the video.

LikeLike

Hi

Thank you very Much for The script, looking forward to test it.

I just recently discovered your channel on YouTube and your Channel has become my favourite 😀

I also Saw your video on inverted pendulum.

In this project you show a lot of graph-plots but how do you make these graph?

I did not see any plotting library in your python Code.

/ michael

LikeLike

Here is the script for graph videos:

https://www.dropbox.com/sh/pem1mbpp82pbgwz/AAAc5Uqdah6dsNdRhJ95bmCBa?preview=log_to_video.py

LikeLike

I just wanted to say I read the entire write-up and I gotta say it was super interesting! I’m amazed by how much time (and money, what, 600ish euros?!?) you invested into this. The fact that you looks up the wavelength absorption of water to troubleshoot, which I never would have thought of, is just awesome problem solving. It’s clear you put in an immense amount of effort, and I can’t wait to see what your mind comes up with next!

LikeLiked by 1 person

Thanks. 600 EUR sounds about right. You can get it down to 400 if you use lead instead of tungsten and replace Lego rechargeable battery box (over 100 eur) with something cheaper.

LikeLiked by 1 person

Pingback: Making a small working submarine with LEGO and Raspberry Pi #PiDay #LEGO @Raspberry_Pi « Adafruit Industries – Makers, hackers, artists, designers and engineers!

Pingback: Making a small working submarine with LEGO and Raspberry Pi - PiShop Blog

Pingback: ICYMI Python on Microcontrollers Newsletter: CircuitPython Day Friday, Python Still #1 and much more! #CircuitPython #ICYMI @micropython @Raspberry_Pi « Adafruit Industries – Makers, hackers, artists, designers and engineers!

Pingback: ICYMI Python on Microcontrollers Newsletter: CircuitPython Day Friday, Python Still #1 and much more! #CircuitPython #ICYMI @micropython @Raspberry_Pi – Best Soundcloud Rappers 2019

Hi

First of all thank you create this great work. we want to make a new one just like you do, we find missing detial circuit diagram. so can you help me to figure out how to connect each component.

LikeLike

Hi. I added a new diagram to the electronics page. Hopefully that will clear out things for you. Zoom in to see the small texts. Here is a link to the image:

I also suggest you check the GPIO assignments from the code. See what pin id is given to each Device and Button object. That way you can be sure the pin does the right thing. Here is a GPIO pinout mapping to see where they are physically located:

LikeLike

Thanks a lot of your youtube and open source information:

My grand sons have very interssting. We would like to make this awersome U-Boot

Have a Helty and best progress

LikeLike

Did you write the code by throwing the operating system into the raspberry or did you throw the codes into an sd card?

LikeLike

I installed an operating system (Raspberry Pi OS) into an SD card. Then I booted the Raspberry Pi with the card and used Thonny (a Python IDE program) to write and execute the code.

More details here: https://brickexperimentchannel.wordpress.com/2022/07/13/rc-submarine-4-0-electronics-8-10/

LikeLike

I tried to Install Routed Wireless Access Point on my raspberrypi zero 2w card but I couldn’t do it completely. I followed the instructions but it didn’t work. Can you help me about it?

LikeLike

If I remember correctly, the steps I took were these:

-install and enable hostapd

-install dnsmasq

-change /etc/dhcpcd.conf to hold nothing but the example content from documentation

-change /etc/dnsmasq.conf to hold nothing but the example content from documentation

-create /etc/hostapd/hostapd.conf with the example content, but different ssid and wpa_passphrase

-reboot

-after reboot I see the ssid on my laptop and can connect to it

Documentation is this:

https://www.raspberrypi.com/documentation/computers/configuration.html#setting-up-a-routed-wireless-access-point

LikeLike

To enhance range you could create a buoy attached by an antenna to the raspberry pi. you sacrifice some speed and maneuvering through cluttered areas but gain range.

LikeLike

How to convert lego cable to jumper cable

LikeLike

Is there maybe a way to build a low frequency controller on your own ?

LikeLike

do you got a parts list for the Submarine 2.0?

LikeLike

You can find key components listed in the Submarine 2.0 video description. But that is all. I don’t have a full part list available.

LikeLike

hi,I’m having some code problems with the pressure sensor, can you help?

The sensor I am currently using: ABPMRRN005PD2A3

How can I use this? I tried a few codes but it didn’t work.

program started

Traceback (most recent call last):

File “/home/pi/Desktop/submarine_4/submarine_4değitü.py”, line 326, in

pressure, pressureSensorTemp = readPressureSensor()

File “/home/pi/Desktop/submarine_4/submarine_4değitü.py”, line 81, in readPressureSensor

bus.write_i2c_block_data(PRESSURE_SENSOR_ADDR, 0xAA, [0x00, 0x00])

TimeoutError: [Errno 110] Connection timed out

I get this error.

LikeLike

Hi. Well… I have never used an APB series sensor. The ones I tested for this project were APB2 and SSC. But, after googling I think the APB series communication protocol is the same as SSC series. So the submarine4.py code should work. Not 100% certain.

Your sensor output type is 2 = I2C with address 0x28. That should work with the code.

Other than that, the only thing is to check everything:

check that I2C is enabled

check the wiring on the sensor (I find it always difficult to correctly orient the layout from the specs)

check the wirings on the Raspberry (or whatever you are using)

measure that the sensor Vsupply pin is getting 3.3V

LikeLike

I will try this, thank you for your quick reply.

LikeLike

Hi, I’m having some problems with my code.

raceback (most recent call last):

File “/usr/lib/python3/dist-packages/serial/serialposix.py”, line 322, in open

self.fd = os.open(self.portstr, os.O_RDWR | os.O_NOCTTY | os.O_NONBLOCK)

FileNotFoundError: [Errno 2] No such file or directory: ‘/dev/serial0’

During handling of the above exception, another exception occurred:

Traceback (most recent call last):

File “/home/pi/bysj.py”, line 107, in

serial = Serial(“/dev/serial0”, 115200, timeout=0.01)

File “/usr/lib/python3/dist-packages/serial/serialutil.py”, line 244, in init

self.open()

File “/usr/lib/python3/dist-packages/serial/serialposix.py”, line 325, in open

raise SerialException(msg.errno, “could not open port {}: {}”.format(self._port, msg))

serial.serialutil.SerialException: [Errno 2] could not open port /dev/serial0: [Errno 2] No such file or directory: ‘/dev/serial0’

could you tell me how to deal it,and what is /dev/serial0.

thanks!

LikeLike

Check these two:

1) You have serial port enabled in raspi-config

2) /boot/config.txt contains enable_uart=1

LikeLike